How thin can a 3D printer print?

Explore the limits of 3D printing technology as we delve into the question: how thin can a 3D printer print? This guide unfolds the intricacies of achieving fine prints, shedding light on nozzle sizes, wall thickness, and the tweaks that can make all the difference.

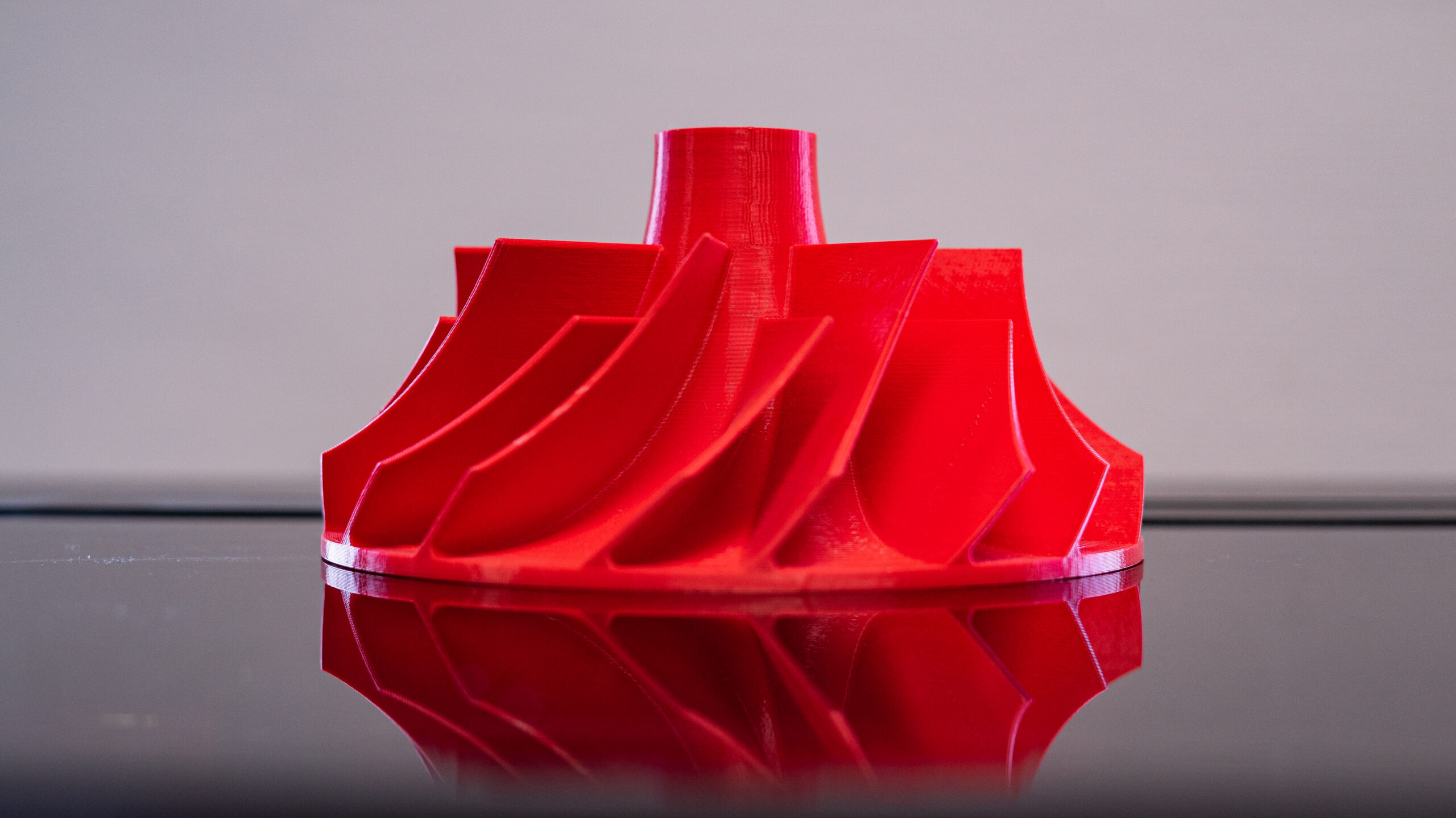

With FDM printing, a model is constructed by printing layers of filament (plastic). This filament is heated until it melts and is then guided through the nozzle of the printer. The width of the layer that is printed onto the print bed is partly determined by the size of the nozzle. Several sizes are available, to enable printing different wall thicknesses (extrusion widths). When printing thin-walled models, it’s good to know how this exactly works. When the wrong settings are used, it could happen that a wall isn’t constructed correctly or not even printed at all. This often happens when models are scaled down.

Different nozzle sizes

The various nozzle sizes can be used for different purposes. Do you want a model to be printed quickly, without paying too much attention to the details? Then choose a big nozzle size like 1.0mm. This nozzle prints a wide and high layer, resulting in less required layers and therefore a quicker result. However, if you want to print a detailed or thin-walled model, you should choose a smaller nozzle, like 0.2 or 0.4mm.

Too thin walls

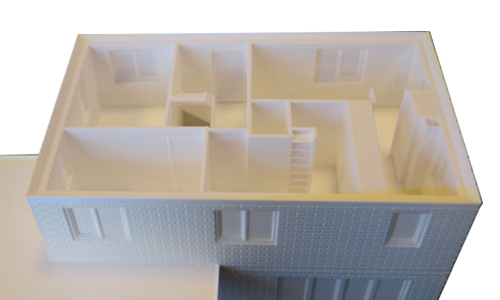

Sometimes, models need to be scaled to a different size. This can be done in the CAD program, but also in slicing software like Simplify3D (which is software that converts a 3D model into a printable file). To acquire the best result, it’s advisable to always scale a product in the CAD program. When scaling down a model, it could happen that walls become too thin to be printed. Most 3D printers have a set nozzle size with a diameter of 0.4mm or 0.5mm. Although this works for most models, problems could arise when layers smaller than this nozzle size need to be printed. When for instance a 0.2mm thick wall has to be printed with a 0.4mm nozzle, this wall will not be shown in the Simplify3D preview and not be printed. There are two possible ways to ensure these walls will be printed (correctly).

Change the design

Firstly, the model can be changed in the original CAD program. Make sure the walls are at least as big as the nozzle size. The walls can also be a bit bigger than the nozzle, 20% at the most. When all walls have been adjusted, the model can be imported into the slicer software again.

Change the nozzle

The second solution is to install a smaller nozzle. The dddrop 3D printers have been built in such a way that it’s easy to change the nozzle. You can choose from nozzles in the sizes 0.2, 0.4, 0.6, 0.8 or 1.0mm. This enables you to print with a high speed as well as detailed thin-walled products.

Material Considerations for Thin Printing

The choice of material significantly impacts how thin a 3D printer can print. Different materials have distinct melting points and flow characteristics. For instance, PLA is easier to print thin compared to ABS due to its lower melting point and less warping. It’s crucial to choose a material that flows smoothly at the set printing temperature, adheres well to the print bed, and solidifies quickly to maintain the thin structure. Experimenting with different materials and noting their behavior helps in mastering thin printing, ensuring the desired precision and quality in your projects.

Software Settings for Optimized Thin Printing

The role of software settings is indispensable when exploring how thin a 3D printer can print. Key settings include layer height, wall thickness, and printing speed. A lower value for layer height results in finer layers, while the wall thickness setting ensures the structural integrity of the model. Slowing down the printing speed allows for more accurate material deposition, which is crucial for achieving thin prints. Mastering the interplay of these settings in your slicing software is a significant step towards successful thin printing endeavors, leading to higher precision and quality in your projects.

Common Challenges and Solutions in Thin Printing

Venturing into thin printing presents unique challenges. Common issues include nozzle clogs, warping, and adherence problems, mainly when working with materials that contract upon cooling. Addressing these challenges entails regular maintenance to prevent nozzle clogs and optimizing bed temperature to enhance adhesion and reduce warping. Additionally, employing a heated print bed and an enclosure can provide a stable printing environment, mitigating the effects of rapid cooling. By understanding and addressing these challenges, one significantly improves the chances of achieving successful thin prints, marking a stride towards mastering the art of thin 3D printing.

Conclusion

As we’ve navigated through the aspects influencing how thin a 3D printer can print, it’s evident that the right balance of hardware, software, and knowledge is crucial. Whether you’re scaling down a model or choosing the perfect nozzle, every detail counts towards achieving those precise, thin prints.

FAQ

How thin is too thin for a 3D printer?

The minimum thickness a 3D printer can achieve is determined by its hardware, particularly the nozzle size. For a standard 0.4 mm nozzle, the thinnest line it can technically print is 0.24 mm, which is achieved by adjusting the line width parameter in the slicing software. There are experimental settings in some slicing software like Cura that might allow for printing thinner walls, but they come with their own set of challenges.

What is the thinnest layer a 3D printer can print?

The thinnest layer height, or Z resolution, is typically around 0.025 mm or 25 microns for SLA 3D printers, and around 0.1 mm or 100 microns for FDM 3D printers.

Is 0.2 mm good for 3D printing?

A 0.2 mm layer height is a common setting for FDM 3D printers when a balance between detail and printing time is desired. It provides a good level of detail while not being as time-consuming as finer layer heights like 0.1 mm.

What is the minimum line thickness for 3D printing?

The minimum line thickness for 3D printing is often equated to the nozzle diameter of the 3D printer. For instance, with a 0.4 mm nozzle, a minimum line width of 0.24 mm is achievable.