The advantages of the material PET-G Carbon

In the ever-evolving domain of additive manufacturing, the innovation of carbon fiber filaments has marked a significant milestone, paving the way for many industrial applications. Utilized in a carbon fiber 3D printer, this specialized filament embodies a unique blend of carbon fibers and thermoplastic materials, tailored meticulously for Fused Deposition Modeling (FDM) technology. When extruded through a carbon fiber 3D printer, the filament melds into a solid structure, embedding the carbon fibers within, thereby imparting a remarkable strength-to-weight ratio to the printed parts. This distinct characteristic of carbon fiber 3D printing is a linchpin in applications where both durability and weight are critical determinants. The ensuing sections delve into the intricacies of PET-G Carbon, the ease of printing with this material, and a deeper exploration of its applications across various industries.

Advantages of PET-G Carbon

In the realm of FDM 3D printing, PLA (Polylactic Acid) emerges as a well-known and frequently utilized printing material, primarily due to its cost-effectiveness and relatively simple usability in 3D printing endeavors. However, PLA exhibits certain limitations, notably its lackluster heat resistance, which could pose challenges in specific applications. Fortunately, the continuous innovation in 3D printing materials has birthed a plethora of options, catering to a wide array of application needs.

Among the notable materials is PET-G Carbon, which stands as a robust contender in the lineup of 3D printing materials. The dddrop 3D printers, in particular, have been meticulously engineered to offer a broad spectrum of material choices, thanks to the dddrop open filament policy. This policy transcends the mere freedom of selecting any filament supplier; it extends to the liberty of choosing any material, thereby enriching the 3D printing experience. The encapsulated casing with temperature control, coupled with a heated printer bed, empowers the creation of models from a multitude of materials, thus expanding the horizons of what can be achieved with 3D printing.

In this segment, the spotlight is cast on PET-G Carbon, exploring its core attributes and the advantages it brings to the table. The fusion of carbon fibers with the base material PET-G culminates in a filament endowed with enhanced qualities. Carbon fiber, known for its remarkable strength, imbues the filament with heightened sturdiness and rigidity. This augmentation in hardness significantly mitigates the risk of scratches or other forms of damage when a 3D printed model interacts with other objects. However, it’s crucial to note that the increased hardness makes the material more susceptible to breakage upon impact compared to regular PET-G filament.

PET-G, in its pristine form without the carbon fibers, is famously recognized in the form of PET-bottles used for housing sodas. This form of PET-G exudes a shiny appearance; however, the infusion of carbon fiber alters its aesthetic to a matte and anthracite hue, which could be a desirable trait for certain applications.

In the subsequent sections, the ease of printing with PET-G Carbon and its alternative for larger models, PA Carbon, will be explored further, diving into the practical aspects of using these materials in a carbon fiber 3D printer.

Understanding Carbon Filament

Carbon filament, specifically carbon fiber-reinforced polymer, is at the heart of the enhanced performance characteristics seen in certain 3D printing materials. In the case of carbon filled filament, tiny fibers are infused into the base material, in this instance, PET-G, to elevate the inherent qualities of the material. Carbon fibers are renowned for their outstanding strength, which renders it considerably more robust and rigid when incorporated into the filament.

Integrating carbon fibers does more than enhance the strength; it also significantly reduces the risk of scratching or other forms of damage when a 3D printed model interacts with other objects. This is particularly beneficial in applications where the model may be subject to physical contact or abrasion. However, it’s essential to note that while the hardness increases, the material is more prone to breaking when dropped than regular PET-G filaments. This trade-off needs to be considered based on the specific use case and the environment in which the printed object will be used.

The aesthetic transformation that accompanies the addition of carbon fiber is also noteworthy. Unlike the shiny appearance of traditional PET-G, the carbon-filled variant takes on a matte and anthracite-colored finish, which might be preferable for applications seeking a sleek, professional look.

The mechanism behind incorporating carbon fibers into the filament is a fine-tuned process that ensures even distribution of the fibers within the material, thus ensuring consistent properties throughout the printed model. The carbon fibers are not merely surface additives; they become an integral part of the material structure, significantly enhancing its performance metrics.

Ease of Printing with PET-G Carbon

Transitioning to a specialized filament like PET-G Carbon comes with its share of considerations, yet, the learning curve is not steep, making it a viable option for a range of users. One of the appealing aspects of printing with PET-G Carbon is that the printer settings required are largely similar to those used for standard PET-G filament. This familiarity in settings simplifies the transition and allows users to leverage their existing knowledge while exploring the enhanced capabilities of PET-G Carbon.

The working temperature for PET-G Carbon stands at 80°C, a parameter that ensures the material does not warp, thereby aiding in the retention of the shape of the printed models. This is a significant advantage, especially in applications where dimensional accuracy and structural integrity are crucial. The non-warping characteristic also reduces the likelihood of printing failures, saving both time and material resources.

Despite the ease of printing, it’s important to acknowledge that PET-G Carbon is an abrasive material. The embedded carbon fibers, while enhancing strength, also increase the wear on the brass nozzle of the printer. This is a common challenge faced when printing with abrasive materials and may necessitate the use of a hardened or stainless steel nozzle to mitigate the wear and prolong the lifespan of the printer nozzle.

The journey of exploring PET-G Carbon accentuates the versatility and growth within the 3D printing material spectrum, highlighting the potential to achieve strong, durable, and aesthetically pleasing prints with relative ease. As we transition to discussing PA Carbon in the ensuing section, the narrative continues on the path of unveiling the robust material options available for a carbon fiber 3D printer, each with its unique set of advantages and considerations.

PA Carbon

When the objective is to print larger models, the properties of PET-G Carbon may fall short in meeting certain requirements. In such scenarios, PA Carbon emerges as a viable alternative that holds promise for delivering the desired performance characteristics. The PA in PA Carbon refers to polyamide, a type of polymer that is known for its excellent mechanical and thermal properties.

One of the prominent PA Carbon filaments is Novamid® ID 1030 CF10 from DSM, which is a concoction of PA 6/66 along with carbon fiber. The incorporation of carbon fiber into the polyamide matrix elevates the strength, stiffness, and hardness of the filament, making it a more suitable candidate for larger models. Furthermore, the carbon fiber infusion results in a filament that is lighter and offers commendable resistance to collision and heat, properties that are often requisite in larger 3D printed models.

The heat resistance is particularly noteworthy as Novamid® ID 1030 CF10 can withstand high temperatures without distorting, a feature that is paramount in applications where the printed parts may be exposed to elevated temperatures.

However, it’s worth mentioning that the journey of printing with PA Carbon, particularly Novamid® ID 1030 CF10, comes with its share of challenges owing to its high-tech nature. Unlike PET-G Carbon, PA filament requires a more refined set of print settings to achieve optimal results. This necessitates a deeper understanding and perhaps a more experienced hand at managing the print parameters to ensure successful prints.

The team at dddrop has conducted extensive testing to derive the correct print settings for Novamid® ID 1030 CF10, easing the path for users. The use of Magigoo PA, for instance, is recommended for perfect adhesion to the 3D printer bed, ensuring that the prints remain stable throughout the printing process.

In a nutshell, PA Carbon, and specifically Novamid® ID 1030 CF10, opens the doors to printing larger carbon models with a carbon fiber 3D printer. While it may demand a higher level of expertise and attention to print settings, the payoff in terms of strength, heat resistance, and size capabilities is significant. Through the lens of PA Carbon, we continue to explore the expansive realm of carbon fiber 3D printing, each material bringing its unique set of advantages to the fore, and catering to a broad spectrum of application needs.

Applications of Carbon Fiber 3D Printing

The use of carbon fibers in 3D printing expands its applications due to its strength and reduced weight.The use of carbon-filled filaments, such as PET-G Carbon and PA Carbon, opens up a world of possibilities in fields where these characteristics are crucial.

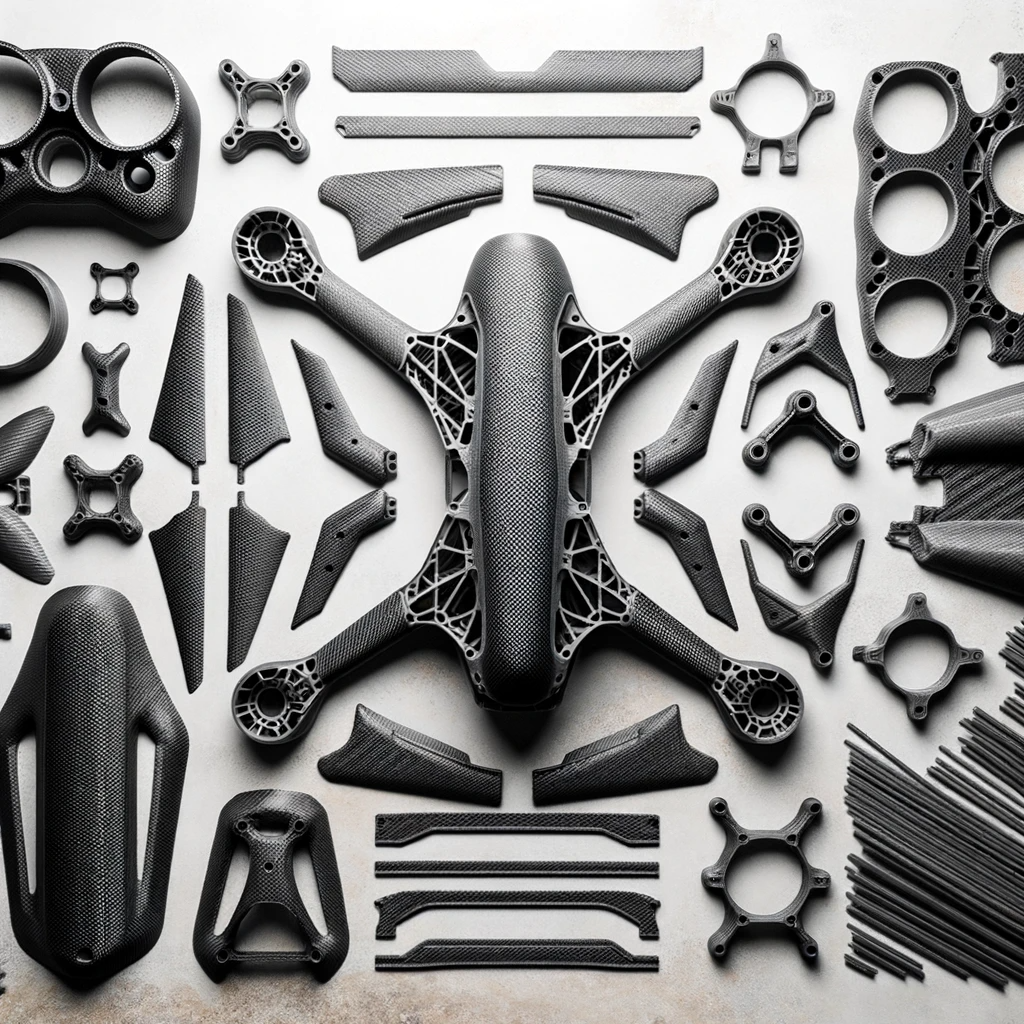

One of the most vibrant arenas where carbon fiber 3D printing shines is in the construction of drones. The strength-to-weight ratio is crucial for drone components, as it directly impacts the flight efficiency and durability of the drone. Carbon fiber 3D printed parts provide the requisite strength while keeping the weight minimal, thus contributing to enhanced flight times and overall performance.

The quest for lightweight yet strong materials is incessant in the automotive industry. Carbon fiber 3D printing aligns well with this pursuit, offering a means to fabricate robust, lightweight parts capable of withstanding the rigorous conditions inherent in automotive applications. From structural components to aesthetic enhancements, the utilization of carbon fiber filaments adds a new dimension to automotive design and manufacturing.

The prosthetics field also benefits immensely from carbon fiber 3D printing. Creating prosthetic limbs and supports that are both lightweight and strong can significantly enhance the comfort and mobility of individuals who rely on these devices. The customizable nature of 3D printing and the superior properties of carbon fiber filaments pave the way for personalized, durable, and functionally efficient prosthetic solutions.

Conclusion

Exploring carbon fiber 3D printing unveils a world full of potential and new ideas. Through the details of PET-G Carbon and PA Carbon, we’ve seen how carbon fiber 3D printing becomes a strong player in modern manufacturing. By blending carbon fibers with plastic materials using a carbon fiber 3D printer, we open a door where strong materials can also be lightweight. As different industries grow, the need for such materials increases. Carbon fiber 3D printing steps in to meet these needs, showing its worth in various fields like drones, cars, and prosthetics. The dddrop 3D printers show us the beauty of having a variety of material choices, pushing the spirit of innovation in the 3D printing world further. This freedom to choose and experiment with different materials showcases a future where we can tailor materials to specific needs, enhancing performance. Our journey into carbon fiber 3D printing is just a glimpse into what’s possible, setting the foundation for more discoveries in materials and printing technologies. Each layer we print is a step towards a future where the limits of what a carbon fiber 3D printer can do are constantly pushed further. This story of carbon fiber 3D printing shows us the exciting transformations additive manufacturing can bring, inviting us to a future full of endless opportunities.