Can you 3D print rubber?

The realm of 3D printing presents endless possibilities with a plethora of materials to choose from. However, not all materials are fit for the 3D printing process, and rubber is one such example. The core question arises: can you 3D print rubber? The answer is a straightforward no. Rubber is a gummy material traditionally hot-pressed into a mold, where it cools down and undergoes vulcanization. Through vulcanization, rubber transitions to a solid state, retaining its shaped form. Unlike other materials used in 3D printing, rubber does not revert to a fluid state upon reheating; instead, it burns, making it unsuitable for the process. For successful 3D printing, the material must transition to a fluid state controllably, a characteristic that rubber lacks. Hence, the quest to 3D print rubber meets a dead end at the fundamental level of material properties and the inherent process of 3D printing.

What is possible?

Synthetic materials such as Thermoplastic elastomers (TPE’S) are good substitutes for rubber. TPE’s are suitable for printing. TPU filament is such TPE, it has the same flexibility as rubber but it will melt at 60°C. Rubber is an organic material: the properties of rubber cannot be affected. However, with TPU we’re able to determine for instance the hardness, the heat resistance and abrasion. We’re imitating the organic material, but we make sure to get the desired and most optimal properties.

TPE’s, including TPU, are used for various applications in the industry. You can think of shoe soles, but also industrial applications such as sealing rings are a good example.

Check the video below for an example we made with TPU (flex) filament during the Olympics in 2016:

Material Comparison

When venturing into the domain of 3D printing with the aim of creating flexible objects, the choice of material is paramount. While rubber, due to its inherent characteristics, falls short of being a viable option for 3D printing, several synthetic materials step up to fill this void. Among these, Thermoplastic Elastomers (TPEs) are prominent for their rubber-like flexibility and 3D printability. A notable member of the TPE family is Thermoplastic Polyurethane (TPU), which melds the flexibility of rubber with the meltable nature required for 3D printing. In this section, we’ll dissect the core differences between rubber and TPU, shedding light on their respective properties and how they fare in various applications.

- Flexibility and Durability: Rubber is renowned for its elasticity and durability. However, TPU also offers a commendable level of flexibility, which can be tailored by modifying the printing parameters, a feature rubber lacks.

- Melting Point: The necessity for a material to have a controllable melting point for 3D printing puts TPU in the spotlight. Unlike rubber that burns upon reheating, TPU melts at around 60°C, making it a suitable candidate for 3D printing.

- Heat Resistance and Abrasion: While rubber maintains its properties across a wider temperature range, TPU’s heat resistance can be adjusted to suit the application. Additionally, TPU showcases good abrasion resistance, mimicking yet another favorable trait of rubber.

- Organic vs Synthetic: Rubber, being organic, has a fixed set of properties. On the flip side, TPU, a synthetic material, allows for a level of customization in terms of hardness, heat resistance, and other properties, making it a versatile choice for varied applications.

- Industrial Applications: Both materials find their places in industries, with rubber being a classic choice for seals, tires, and damping systems, while TPU shines in applications like shoe soles and sealing rings, where a balance of flexibility and printability is sought.

- Cost and Availability: TPU’s rising popularity in the 3D printing realm has made it relatively easily available and cost-effective, especially when compared to the traditional rubber manufacturing processes.

Understanding the distinctions between rubber and TPU, alongside their respective advantages and limitations, can guide individuals and industries in making informed decisions when it comes to selecting materials for 3D printing flexible objects.

Pros and Cons of TPU for 3D Printing

Thermoplastic Polyurethane (TPU) has emerged as a go-to material for individuals and industries looking to 3D print flexible objects. Its properties provide a close resemblance to rubber while also being adaptable to the 3D printing process. However, like any material, TPU has its share of advantages and disadvantages when it comes to 3D printing. This section aims to delineate the pros and cons of utilizing TPU for 3D printing applications.

- Pros:

- Flexibility: TPU is highly flexible and can mimic the elasticity of rubber, making it ideal for a plethora of applications where flexibility is a requisite.

- Customizability: The hardness, heat resistance, and abrasion properties of TPU can be tailored to meet specific requirements, offering a level of customization that is hard to achieve with traditional rubber.

- Durable: TPU is known for its durability and resistance to abrasion, wear, and tear, which is crucial for industrial applications.

- Recyclability: Being a thermoplastic material, TPU can be recycled, which is beneficial from an environmental standpoint.

- Wide Range of Applications: From consumer goods like shoe soles and phone cases to industrial applications like sealing rings and hoses, TPU’s versatility is commendable.

- Cons:

- Printing Difficulty: Printing with TPU can be challenging, especially for beginners. It requires a well-calibrated printer and a good understanding of the printing settings.

- Printing Speed: TPU requires a slower printing speed compared to more rigid materials like PLA or ABS to ensure accurate deposition and to prevent issues like stringing.

- Printer Compatibility: Not all 3D printers are equipped to handle the flexibility of TPU. Printers with a direct drive extruder are generally better suited for printing with TPU.

- Cost: While TPU might be more cost-effective compared to some materials, it can still be on the higher side price-wise, especially when compared to more common 3D printing materials like PLA.

Understanding the benefits and challenges associated with TPU for 3D printing can aid individuals and enterprises in making informed decisions regarding whether it’s the right material for their specific projects. With the right equipment and expertise, the hurdles associated with TPU can be navigated, unlocking its full potential in 3D printing applications.

Application Examples of 3D Printed TPU

The versatility of Thermoplastic Polyurethane (TPU) transcends into a myriad of applications, where its rubber-like flexibility coupled with the precision of 3D printing brings forth innovative solutions. Below are some notable application examples of 3D printed TPU, demonstrating its potential in both consumer and industrial realms.

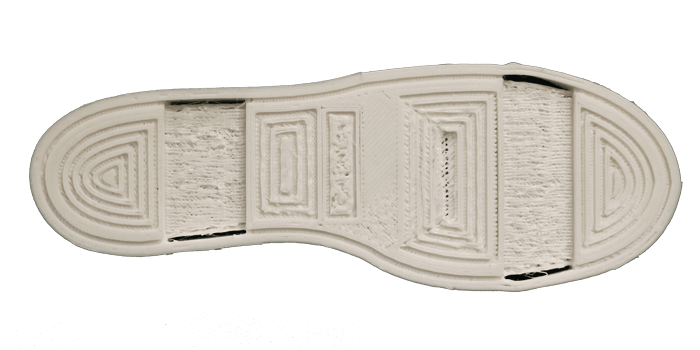

- Footwear:

- TPU is extensively used in the footwear industry to create flexible yet sturdy shoe soles. 3D printing with TPU allows for customized designs catering to different footwear needs, be it athletic shoes, orthopedic insoles, or fashion-forward footwear.

- Sealing Rings:

- The material’s inherent flexibility and durability make it a prime choice for manufacturing sealing rings. 3D printed TPU sealing rings can be tailored to fit specific dimensions and tolerances, ensuring a snug fit and effective sealing.

- Protective Cases:

- From smartphone cases to protective covers for electronics, 3D printed TPU offers a blend of shock absorption and aesthetic appeal. Its capacity to withstand daily wear and tear while maintaining a sleek appearance is highly valued.

- Medical Devices:

- In the medical field, TPU is utilized for creating flexible components like tubing, cushioning, and various wearable devices. Its biocompatible variants can be employed in direct contact with the body, making it a viable material for medical applications.

- Automotive Components:

- TPU’s resistance to abrasion and flexibility finds applications in the automotive industry for parts like bushings, couplings, and flexible hoses. 3D printing enables rapid prototyping and customization of these components to suit specific vehicle models.

- Gaskets and Connectors:

- The capability of TPU to form airtight seals and withstand mechanical stress makes it a preferred material for gaskets and connectors. 3D printing these parts with TPU can ensure precise dimensions and enhanced performance.

- Sporting Goods:

- Items like custom grips, flexible guards, and performance-enhancing athletic gear can be 3D printed with TPU to cater to the individual needs of athletes, enhancing comfort and functionality.

- Customized Promotional Products:

- The ease of customization with 3D printing allows for the creation of personalized promotional products. TPU can be used to craft unique, branded items that are both functional and visually appealing.

These applications underscore the utility of TPU in the realm of 3D printing, fostering innovation across a broad spectrum of industries. The ability to tailor the material properties and geometries through 3D printing amplifies the advantages of TPU, making it a prized material for tackling complex design challenges.

What should I take into account when printing with TPU?

Printing with TPU is difficult. Therefore it is necessary to practice first with PLA before printing with TPU. TPU needs more time to melt and flow. If you print too fast, the material will collapse. Therefore it’s important to reduce the printing speed. Also, the kind of printer you use is relevant for printing TPU. In case the drive motor is located on the back of the printer, the material is pushed through the entire extruder to eventually melt in the print head. When using printers with a direct drive, where the motor is located in the print head, the filament doesn’t need to be pushed through the entire extruder. It only has to bridge a small distance, until it is melted. Imagine you push an elastic through a tube, the elastic will accumulate: the greater the distance, the more difficult it becomes. If the drive motor is located in the print head, the filament has to bridge a smaller distance. Thus, you need a printer with a direct drive to print well with TPU filament.

How to influence the flexibility?

Several TPE’s are available: ones that are really rigid and others really elastic. However, the elasticity of the final product is not only affected by the used filament. The printing technique also has influence on the elasticity. The thinner you print, the more elastic your product becomes. For example: printing a honeycomb structure creates thin layers with air between them. In this way you can determine which part is more flexible than the other. Thanks to the printing technique you can reach different levels of flexibility. When rubber is vulicanized, the end product is always solid. Thus it isn’t possible to play with the elasticity of rubber.

Alternative Materials for Flexible 3D Printing

While Thermoplastic Polyurethane (TPU) stands as a popular choice for flexible 3D printing, there are other materials in the market that also offer flexibility alongside other distinct properties. Exploring these alternatives can provide a broader perspective and more options when embarking on projects requiring flexible components. Here are some of the alternative materials for flexible 3D printing:

- Thermoplastic Copolyester (TPC):

TPCs are known for their elasticity and chemical resistance. They offer a good balance between flexibility and mechanical strength, making them suitable for applications like industrial tubing and flexible connectors. - Flexible PLA (PolyLactic Acid):

Flexible PLA is a softer variant of the standard PLA material. It offers a level of flexibility while maintaining the ease of printing that PLA is known for, making it a good starting point for those new to flexible 3D printing. - Polyether Block Amide (PEBA):

PEBA is recognized for its high elasticity and strength, resembling rubber-like properties. It’s suitable for applications where excellent mechanical properties and flexibility are required. - FilaFlex:

FilaFlex is a proprietary blend that boasts extreme flexibility, making it one of the most flexible 3D printing materials available. It’s ideal for applications where high flexibility is the priority. - Elastollan (TPU-based):

Elastollan is a type of TPU material but with variations in its formulation to cater to different application needs. It’s available in different grades to match varying levels of hardness and flexibility. - FlexSolid:

FlexSolid is known for its ease of printing and moderate flexibility. It’s a suitable choice for those looking to venture into flexible 3D printing without dealing with the challenges posed by ultra-flexible materials. - Rubber-like Resins (for SLA/DLP printing):

For those utilizing SLA or DLP 3D printing technologies, rubber-like resins are available that simulate the properties of rubber. These resins can achieve fine detail along with flexibility, making them a choice for precise, flexible parts.

Each of these materials brings a unique set of properties and advantages to the table. The choice between them would depend on the specific requirements of the project at hand, such as the degree of flexibility, chemical resistance, ease of printing, and the 3D printing technology being used. By understanding the characteristics of these alternative materials, individuals and organizations can make informed decisions to meet their flexible 3D printing needs best.

Can I combine support material with TPU?

When using support material, you should pay attention to the print and bed temperature. These have to be about the same as the temperature of the used filament. PVA requires approximately the same temperature as TPU and therefore PVA is the best option to combine with this filament. Besides support material, is it possible to combine TPU with another material? Yes, but in this case both should also have the same print and bed temperature. ABS requires a higher temperature than TPU. Therefore this wouldn’t be a good combination, because the TPU filament will melt on the print bed. Also, when printing with two materials, we advise to let the parts fit mechanically together. In this way the parts remain attached to each other, even if the print adhesion doesn’t stick together. More about printing with support material you will read here

Would you like to print flexible 3D models?

Our dddrop EVO Twin 3D printer features a direct drive, so it’s suitable for printing TPU. Furthermore, for optimum print quality, we offer our own dddrop TPU filament. In case you have any questions, please feel free to contact us: info@dddrop.com. We would love to help you.

FAQ

Can you 3D print silicone rubber?

Yes, it is possible to 3D print silicone rubber using specialized 3D printing technology. There are certain types of 3D printers that are designed to handle silicone material, and they extrude liquid silicone rubber (LSR) which is then cured with heat or UV light to solidify. The process allows for the creation of flexible, durable, and heat-resistant silicone parts.

Can you 3D print soft plastic?

Yes, you can 3D print soft plastic materials. Thermoplastic elastomers (TPE) and thermoplastic polyurethane (TPU) are examples of soft plastic materials that are commonly used for 3D printing. They can be extruded through a 3D printer to create flexible and soft plastic parts. The degree of softness can be controlled by adjusting the printing settings and the specific type of soft plastic material used.

Can you 3D print rubber-like material?

Yes, you can 3D print rubber-like materials. As mentioned earlier, materials like TPU and TPE can mimic the properties of rubber to a certain extent. Additionally, there are specific rubber-like resins available for SLA or DLP 3D printing technologies that can produce parts with rubber-like flexibility and feel.