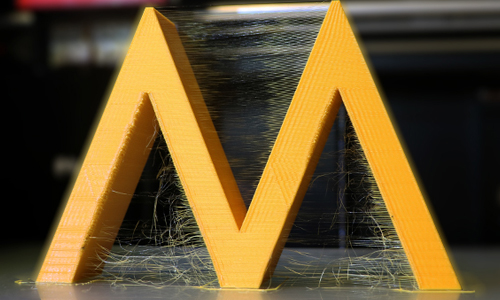

What causes stringing in 3d printing?

When the head of your 3D printer has to move from one point in your model to another, the filament can flow out. The result is stringing: small strands of material appear between the printed parts. Stringing is especially common in models that have large open areas, but there are ways to prevent it.

The right material

Whether stringing occurs varies by material. ABS, for example, hardly causes string formation, but PET-G does. Material composition also has an impact, so the degree of strings can vary by brand of filament.

Retraction setting

It is possible to activate the retraction setting in the slicer software. This functionality ensures that the filament is retracted into the nozzle before the print head moves to another part of the product. The retraction speed is also important, if it is set too low, strands may still appear.

Wipe nozzle setting

This option can be combined with the retraction setting. With sweep nozzle, the printer will sweep the last bit of liquid material on the model before retracting the filament and moving the print head to the next location. In this way, wires are minimized even further.

Temperature

If the filament is still oozing after retraction, the print temperature may have been set too high. The material then becomes very fluid, making retraction more difficult to perform. Check the settings with your filament supplier and adjust the temperature if necessary.

Movement speed

The greater the distance between two points in the model, the harder it is to keep the filament in the nozzle. Therefore, for a model with large gaps, we recommend slightly increasing the movement speed. The movement speed is not the same as the print speed, because it is the movement between print points. Note that the speed should not be set too high either, as this could cause the pinhead to overshoot, causing shifts in the model. So find the right balance.

Is the product still not perfect? Your last option is the finishing: you can clear the model of the last strings with a heat burner or a hairdryer.