How to maintain your 3D-printer?

Maintaining your 3D printer The first hours of printing are behind you and by now your 3D printer has become indispensable to your development and production process. Before you leave for home in the evening, you want to get the printer up and running quickly so that...

3D printing with support material

When do you need to 3D print with support material? The great advantage of 3D printing is that it allows you to print very complex models that are difficult to produce with other techniques. For example, think about printing an overhang. Because 3D printed parts are...

3D design and 3D printing

How to design and print a perfect 3D model? That engineer is a special and great profession needs no further explanation. All objects around us were once developed by an engineer. For years we all produced mainly with the well-known techniques such as mill-turning or...

How thin can a 3D printer print?

How thin can a 3D printer print? Explore the limits of 3D printing technology as we delve into the question: how thin can a 3D printer print? This guide unfolds the intricacies of achieving fine prints, shedding light on nozzle sizes, wall thickness, and the tweaks...

Printing a 3D model that sticks

Printing a 3D model that sticks FDM 3D printing technology uses molten filament (plastic) that is printed onto the print bed through the nozzle. For a perfectly printed model, it is crucial that the first layer of filament adheres well to the print bed. Most filaments...

What to do with overheating filament?

A stable printing process The right temperature remains the code word when making good 3D prints. After all, it remains a plastic process, where temperature is an essential component. With a higher ambient temperature, a number of things will be important to keep the...

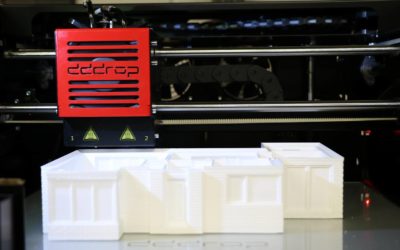

Benefits of printing with a closed chamber

Benefits of printing with a closed chamber Purchasing a 3D printer may result in some stress in choice because there is a lot to choose from. An important difference is the construction of the 3D printer. There are 3D printers on the market without a casing/cabinet,...

What is 3D print delamination and how do you prevent it?

What is 3D print delamination? We talk about delamination in 3D printing when a shrinkage occurs higher up in the print model, during 3D printing. When and how fast a product shrinks depends very much on the type of material you use during printing. PLA and PET-G are...

Closed versus Open 3D printer systems

Closed versus Open systems Where the purchase of a professional 3D printer the first years was only reserved for the major players in the market, 3D printing is becoming more and more accessible. Also a professional 3D printer is becoming more affordable, there are...